One of my favorite shirtmakers is Ascot Chang, a family-run business with almost sixty years of history. Founded in Hong Kong by the eponymous owner and tailor, Mr. Ascot Chang, the company has grown from a small shirtmaking shop in Tsim Sha Tsui to a global custom tailoring business. Throughout that growth, they’ve always kept the same high standards. Each of my shirts from them fits in the exact same way – clean through the chest, torso, and arms, with no pulling or blousing anywhere. The fit is both flattering and functional. And although I’m only able to afford their lower end cotton fabrics, they’re always much better than almost anything I can find off the rack.

I had a chance to speak with Tony and Justin Chang, the son and grandson of the founder, sometime last year (I’ve been sitting on this interview for a while). We talked about the history of their company, a bit about shirt construction, and some of the aspects of how a shirt should fit. It was a special opportunity for me, given how much I admire their work, so I thought I’d end our series on custom shirts with this interview. Click through the cut to read it.

Derek Guy: Tell us about the history of the company. How did it start?

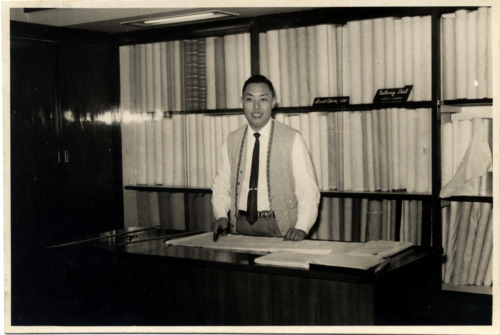

Tony Chang: My father started the company in 1953. Before that, he grew up in a rural part of China, where his parents worked as farmers. When he turned 14, he went to Shanghai and apprenticed under a shirtmaker. That’s how he learned his trade. In 1949, when he was 27 years old, he moved to Hong Kong with the dream of starting his own company. He actually got his start just knocking on doors at the time. By 1953, however, he was able to open up a shop under his own name, Ascot Chang. American and European tourists visiting Hong Kong eventually became quite fond of his work, which is how his reputation spread.

DG: And how did you and your son, Justin, get into the business? And how have you each seen it grow?

TC: I went to school in Montreal, and after I graduated from university, I came back to Hong Kong to work for my father. He had a heart attack just a few years before I graduated, so I came to help out. I didn’t know anything about the business at the time, though. I just knew my father made custom shirts, but little else. After a few years in the business, I started to realize how big my father’s reputation was, and I became more interested in my family’s business. By the mid-80s, just after Justin was born, I opened our first American shop in New York City. Now, we have over fourteen stores in the US and Asia. The shirtmaking business has had its ups and downs in the last sixty years, but ours has been very fortunate to have steady growth.

Justin Chang: My story is fairly similar, actually. I went to Cornell to study Textiles and Apparel Management. It’s a very small, specialized program, and I picked it up partly because I didn’t know what I wanted to study at the time. My father suggested this as something I could look into, and I thought I’d try it out. In my freshman year of college, I worked in the company’s factory a bit, but it wasn’t until I graduated collage and worked in our New York store that I really started realizing how well regarded we were in certain circles. Since I’ve been here, I’ve worked on various things here and there. You may have seen our fashion shows, which are styled by Michael Macko in New York. I’ve worked on those, as well as some of our marketing campaigns. Hopefully, I’ll also be getting into the factory and learning the cutting and sewing side more as well. That’s the heart of our business, after all.

DG: That’s really interesting that you brought up the fashion shows. I’ve always thought of you guys as primarily shirtmakers, but it seems now you have a full menswear line – everything from umbrellas to suits. How long have you had a full line?

TC: It came gradually. We started a ready-to-wear shirt line fifteen years ago, because shirts are what we do best. From there, we’ve worked to find good suppliers. Things such as our polo shirts, for example, are made by another company, so we have had to find the right partners. A few years ago, we started bringing in stylists from New York in order to add some styling to our ready-to-wear range. Now we have a full ready-to-wear line for customers who might have a more standard build. They can just come into our shops and pick up what they need.

DG: So then is the custom line just for suits and shirts?

JC: Yes, but also robes, pajamas, and boxer shorts. Those we do the old English way, and it’s custom.

DG: Have you run into any problems trying to find skilled tailors? I know some regions, such as London, often complain that there aren’t enough trained tailors to carry on their trade.

TC: Training tailors is always a top priority for us. In Hong Kong, we’ve tried to contact various universities about the possibility of creating courses, ones that focus on tailoring or craftsmanship. Most of the courses on fashion focus on design, but not so much the workmanship. We think there’s room for improvement on that. For us, finding skilled tailors is critical since the core of our business since is in custom tailoring. It’s not like a fashion brand, where they can more easily grow and open ten new stores if there is a demand for their goods. If we can only make 200 custom suits a month, that’s it, regardless of how many stores we have or what the demand may be. So we always need to find the right people who can uphold our standards for workmanship.

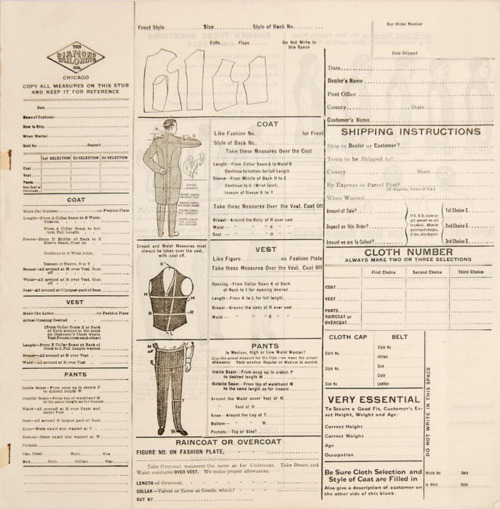

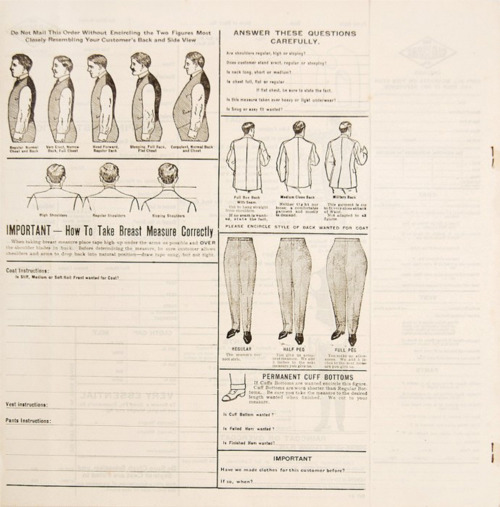

DG: Let’s talk about the process of making a custom shirt. What steps are involved?

TC: It really starts from the measuring process. That’s probably the biggest component of our business. We take multiple measurements, observe the client’s posture, and ask him the kind of lifestyle he plans to wear the shirts in. From this, we create an initial paper pattern, which we’ll adjust until the client is satisfied with the fit. Once we have the paper pattern down, a client can order fabric swatches to be sent to him overseas, or just come to one of our trunk shows and flip through fabric books. He tells us which fabrics he likes, and we’ll make him a shirt and send it to him. If he needs the shirt to be adjusted at some point, he can also come to one of our stores, and we’ll adjust his paper pattern on file. This is what allows us to make a perfect fitting shirt every time, and I think why 70% of our business is from returning customers.

DG: Curious, I know some men like split yokes. Do you find they make a difference in how well you can make a shirt fit?

TC: A split yoke allows you to have one more seam to properly maneuver on a client. For ready to wear shirts, it doesn’t make a difference; it’s just used for style. On custom, we rarely see the need for it. Most of the time, you can maneuver the shirt in the way you need with the existing seams.

DG: I know shirt collars have an interlining in them. Do you know if fused or unfused ones are best?

TC: It’s a matter of preference; we do both. A fused collar will look sharper and crisper, especially after laundering. Businessmen tend to prefer fused. An unfused collar, on the other hand, will look softer and more natural. There are some downsides, however. For one, wrinkles can show up in the collar, though I suppose for some people, that’s part of the charm. Similarly, if you don’t iron your collar correctly, you can press in creases into the collar. Additionally, if the interlining and shirt fabric react differently to washes, you can get the one shrinking slightly more than the other.

I think some people like unfused collars because it’s an older look. When my father was making shirts in the ‘50s and ’60s, fused collars weren’t invented yet, so everything was unfused. When fusing technology first came out, there were a lot of problems with shrinkage and bubbling in the collar, but now fused collars will wear and wash just fine. They just look crisper than unfused ones.

We have different weights and thicknesses for our fused collars, too. For example, if a customer wants something softer and more natural looking, but also wants to keep it wrinkle free, he can choose the softest, lightest fused collar we have.

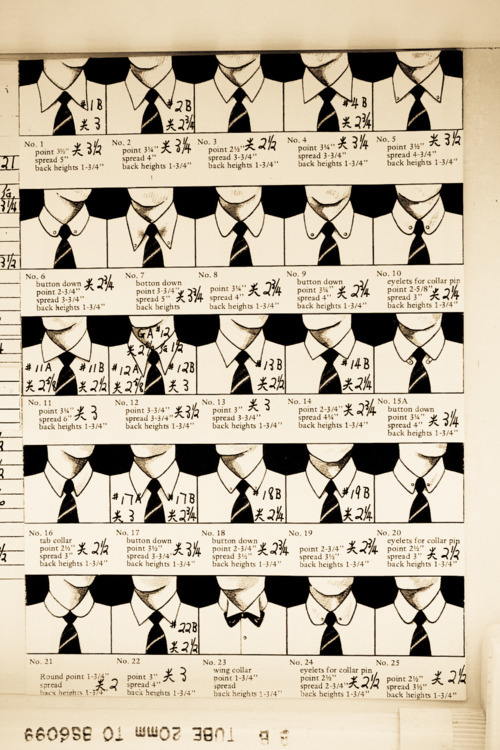

DG: Do you have any advice for men trying to find a collar style that suits them?

JC: Well, first, there are the general rules about matching the spread of the collar to the shape of your face. If you have a narrow face, a wider collar might suit you better. If you have a rounder face, a point collar might be best. I think men have more freedom to break these “rules,” though. Just because you have a rounder face doesn’t necessarily mean you can’t wear a spread collar, and some collar styles, such as a semi-spread, probably suits everyone.

The biggest effect we find is in how long the collar points are. If you have a big head, a small collar will make your head look larger. If you have a small head, a large collar will make your head look smaller. It’s also important to consider collar heights. For example, I have a longer neck, so it’s a bit more important to have a collar height that comes up a bit to compensate for that. Collar style can be important, but so are the length of the points and height of the collar.

DG: What about the other aspects of how a shirt should fit? Do you have any advice?

TC: Of course, we always follow what the customer wants, but we usually suggest something that’s trim but not tight. We call it the medium fit. It’s something where you can sit down, have a full meal, and not have your shirt pull around the buttons. Yet, when you stand up, there also won’t be extra fabric spilling over your pants.

A lot of this also depends on a man’s build. For example, if someone has a heavier build, we wouldn’t suggest a tight fit since it won’t be very flattering. At the same time, when someone is very skinny, we also wouldn’t suggest a tight fit either, otherwise people will notice how thin they are. For both of these builds, we would suggest something slightly fuller than the normal fit, so that they will be presented in the most flattering way possible.

DG: Thank you for your time, Tony and Justin. I really appreciate it.

TC: Same here, Derek. Thank you. It’s great talking to people who have so much interest in menswear.